Sterntube Seal

Total Solution STERN TUBE SEAL DEVICE

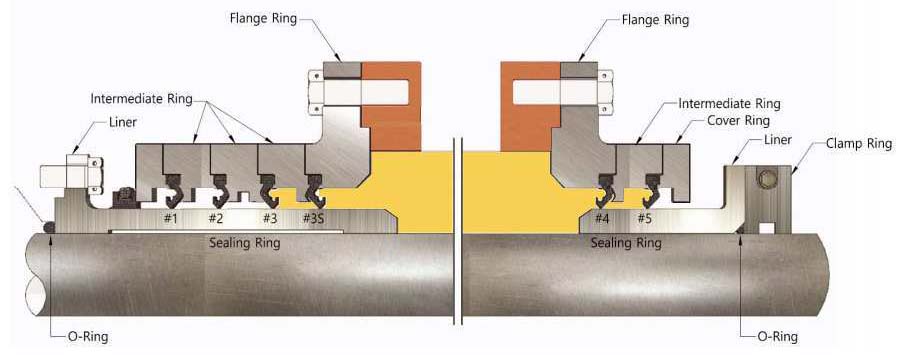

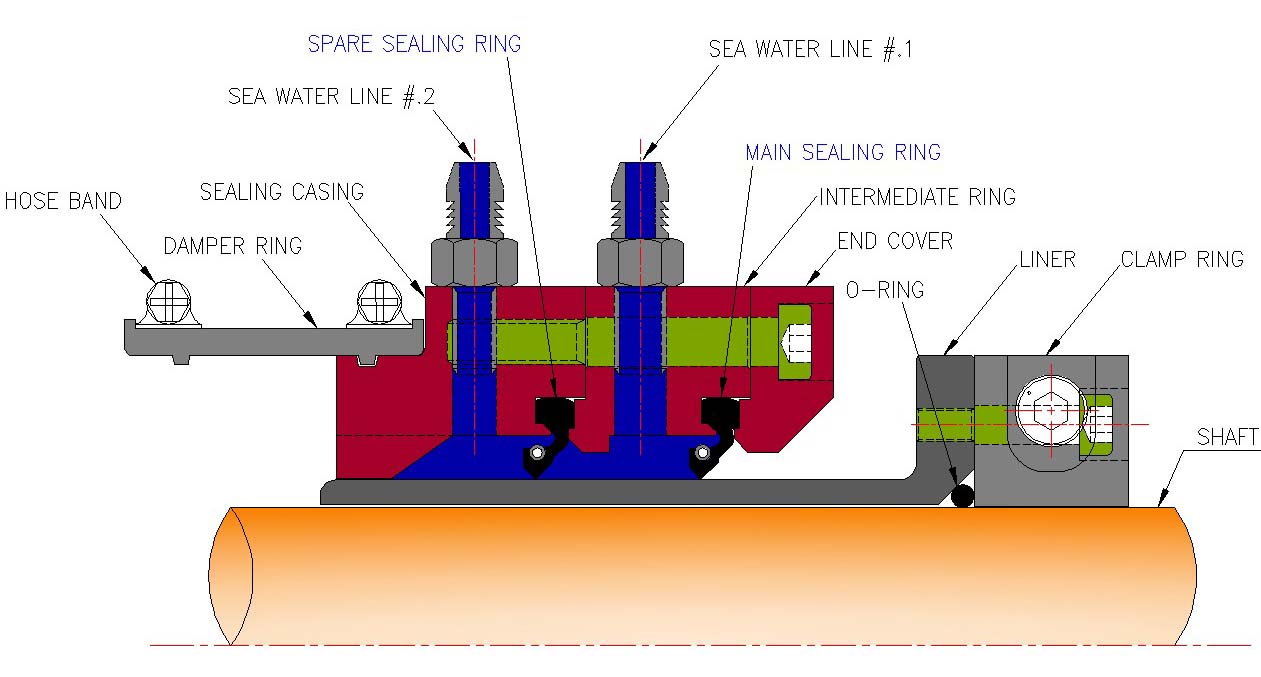

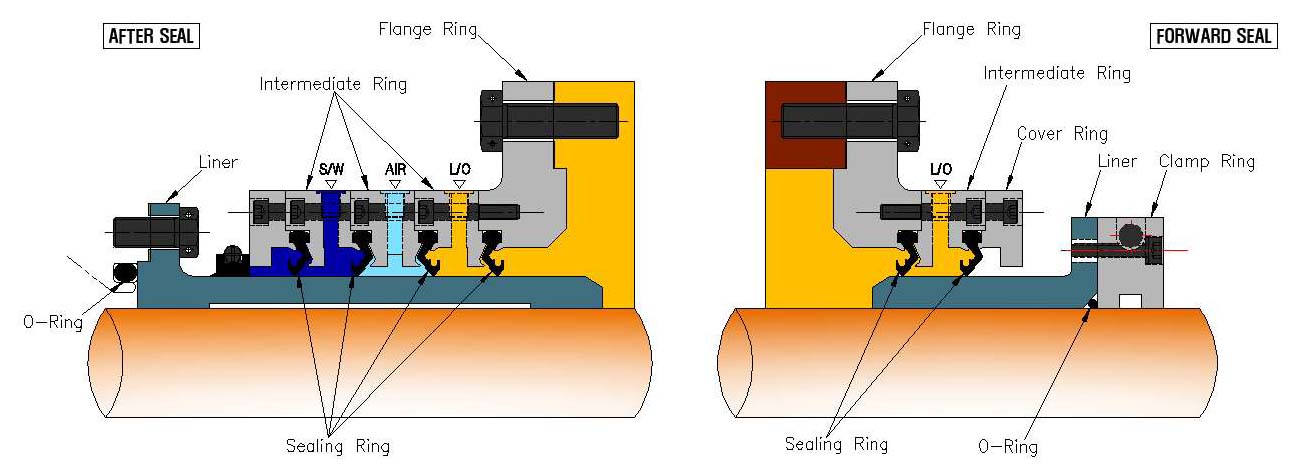

- Oil Lubricant Stern Tube Seal

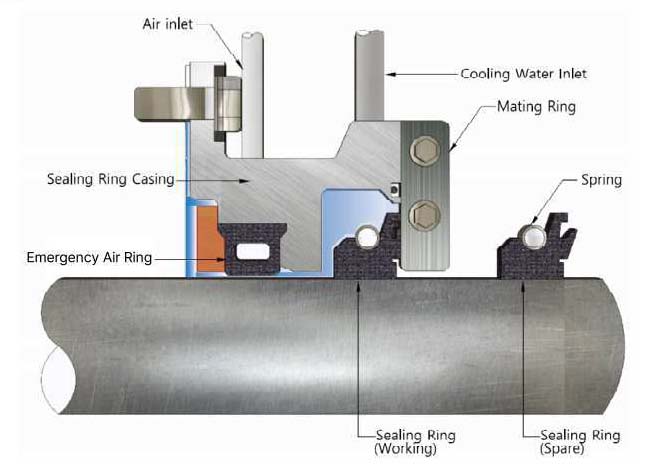

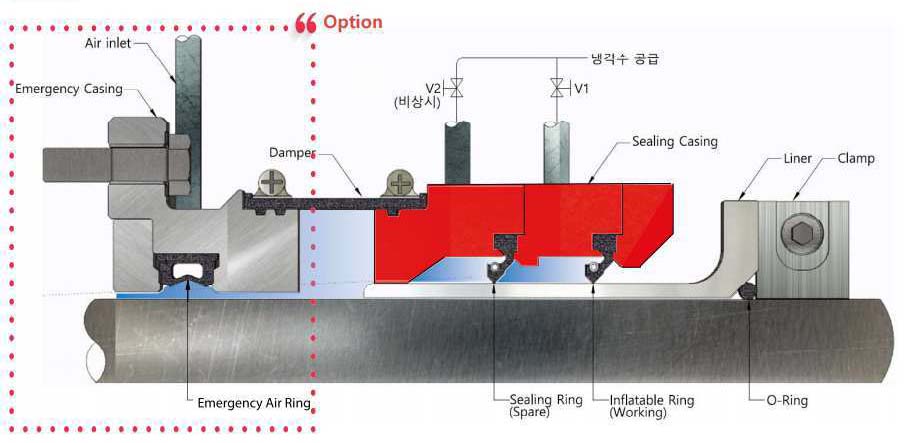

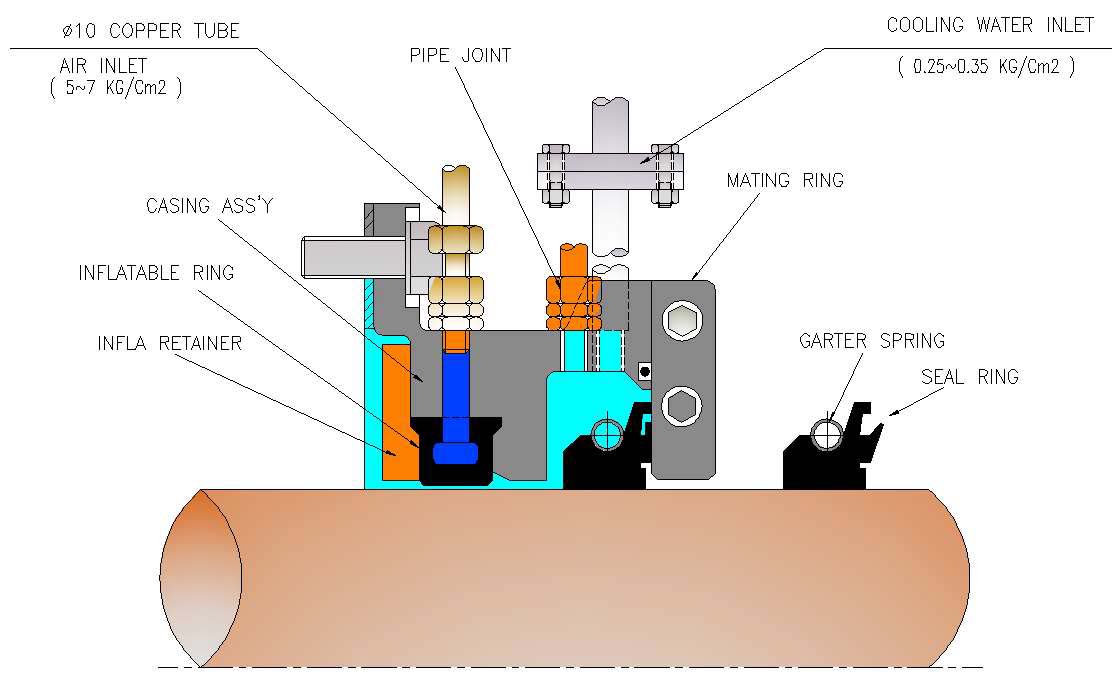

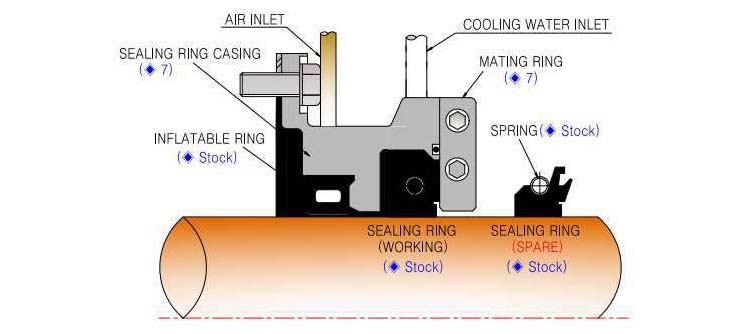

- Water Lubricant Stern Tube Seal

- High-Speed Water Lubricant Stern Tube Seal

- Rudder Stock Seal

- C.P.P And Side Thruster Seal Part

Stern Tube Seals Device: Water Lucricant Type

* Preparation Period in Factory : " xx(day)"

* Application Criteria : Working Day

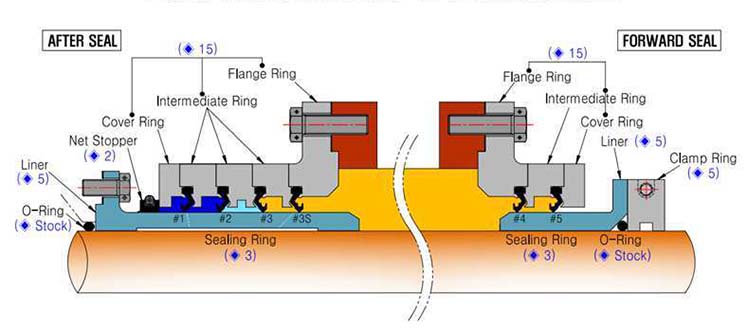

Stern Tube Seals Device: Oil Lucricant Type

* Preparation Period in Factory : " xx(day)"

* Application Criteria : Working Day